- Home

- Products

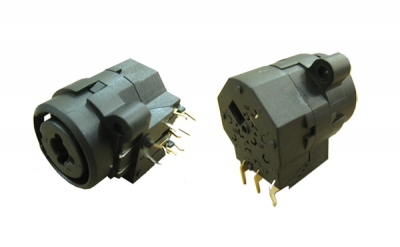

- 6.4& XLR Combo Jack

- K6X01-6-3A

K6X01-6-3A

- SCOPE

- CHARACTERISTICS

- ELECTRICAL CHARACTERISTICS

- MECHANICAL CHARACTERISTICS

- ENDURANCE CHARACTERISTICS

- DIP

This specification covers " 6.4Ø PHONE JACK & XLR JACK " COMBO

Standard atmospheric specified, measurements shall be made at temperature , humidity and air pressure within the following limit :

| Ambient temperature | : | 5 | ℃ | to | 35 | ℃ |

| Relative humidity | : | 45 | % | to | 85 | % |

| Air pressure | : | 85 | Kpa | to | 106 | Kpa |

| Operating temperature range | : | -30 | ℃ | to | 80 | ℃ |

| Storage temperature range | : | -30 | ℃ | to | 80 | ℃ |

| ITEM | TEST CONDITIONS | SPECIFICATION |

|---|---|---|

| (C1) Rated Voltage Rated Current |

50V

7.5A

|

|

| (C2) Insulation Resistance |

A voltage of 500V DC shall be applied to the terminals. After which measurement shall be made. DC 500V |

100M Ω or more≧ 100M Ω

XLR JACK Initial:>2GΩ

After damp heat test:>0.5GΩ

|

| (C3) Contact Resistance |

6.4Ø PHONE JACK Measurement shall be made at 1 K Hz with 100 mA or less (With the test plug as show in item G)

<1>Initial before any testing

a、Pin to contact or (R-RN,T-TN,S-SN) (N.C.).

b、Plug shield to socket or (T,R,S,) (N.O.).

<2>After life test with mating plug

a、Pin to contact or (R-RN,T-TN,S-SN) (N.C.).

b、Plug shield to socket or (T,R,S,) (N.O.).

XLR JACK Measurement shall be made at 1 K Hz with 100 mA or less (With the test plug as show in item H)

<1>Initial before any testing

Plug shield to socket

<2>After life test with mating Plug shield to socket

|

6.4Ø PHONE JACK nitial:

a、≦ 30mΩ

b、≦ 50mΩ

After life test:

a、≦ 60mΩ

b、≦ 100mΩ

XLR JACK Initial:

≦ 30mΩ

After life test:

≦ 100mΩ

|

| (C4) Dielectric Strength |

6.4Ø PHONE JACK Withstand 0.5 mA (Trip current) 500V AC(50 or 60 Hz) between any open terminal for 1 minute. (Open terminal: Between each terminal which should not make contact , before plug insert to socket R-T,R-S, after plug insert to socket R-RN, T-TN, … .) XLR JACK Withstand 0.5 mA (Trip current) 1500V AC(50 or 60 Hz) between any open terminal for 1 minute. (Open terminal: Between each terminal which should not make contact , before plug insert to socket .) |

Without distinct Damage |

| ITEM | TEST CONDITIONS | SPECIFICATION |

|---|---|---|

| (D1) Insertion force and Withdrawal force | Initial ( With the test plug as show in item G for 6.4Ø PHONE JACK) | Insertion force 0.3kgf ~ 3.0kgf |

| Withdrawal force 0.3kgf ~3.0kgf |

||

| After life test ( With the test plug as show in item G for 6.4Ø PHONE JACK) | Insertion force 0.3kgf ~ 3.0kgf |

|

| Withdrawal force 0.3kgf ~ 3.0kgf |

||

| (D2) Terminal strength | ( With the test plug as show in item H for XLR JACK) ( With the test plug as show in item H for XLR JACK) |

Insertion force

0.3kgf ~ 4.0kgf

Withdrawal force

0.3kgf ~ 4.0kgf

Insertion force

0.3kgf ~ 4.0kgf

Withdrawal force

0.3kgf ~ 4.0kgf

|

| (D3)Terminal strength |

Terminals must withstand a 500g minimum pull for 10 seconds before movement or break from housing occurs , but deformation of terminal is authorized .

|

|

| ITEM | TEST CONDITIONS |

|---|---|

| (E1) Life test | 6.4Ø PHONE JACK The life test shall consist of 5,000 cycles of insertion and withdrawal with test plug( Show in item G ), at a rate of 20 to 30 cycles per minute under no load . XLR JACK The life test shall consist of 1,000 cycles of insertion and withdrawal with test plug( Show in item H ), at a rate of 10 to 20 cycles per minute under no load . |

| (E2) Soldering test | The terminal of JACK tested shall be dipped into soldering flux or equivalent for 5 ~ 10 seconds and then immersed into molten solder Sn at 260 ± 5℃ for 3 ± 0.5 seconds , the coverage should more than 95% . |

| (E3) Soldering heat |

The terminal for a printed circuit board .

Temperature of solder : 260 ± 5℃

Dip time : 5 ± 1 seconds .

|

| (E4) Hand Soldering Temperature |

Temperature of solder:350 ± 10℃

Dip time : 3 ± 0.5 seconds .

|

| ITEM | TEST CONDITIONS |

|---|---|

| The temperature peak withoutlead. | .jpg) Pre-heating temperature is 25 ~ 120℃,for a duration about 80 seconds。 The peak temperature is 260℃, the duration for 10 seconds. |